Large-scale professional manufacturer of pressure vessels in Asia

EPC Project

We are the major engineering, procurement, construction, fabrication (EPCF) company from Taiwan, providing total solution EPC services in diverse industries.

Equipment

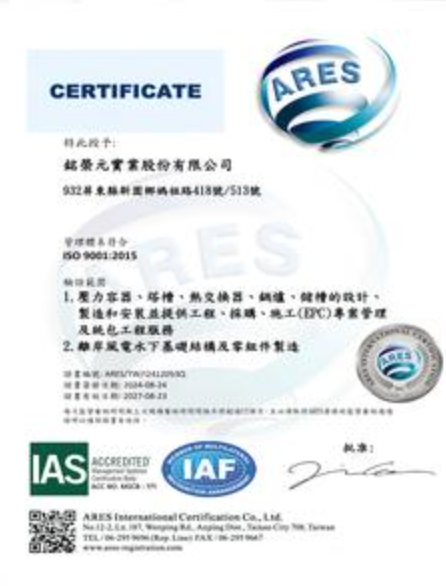

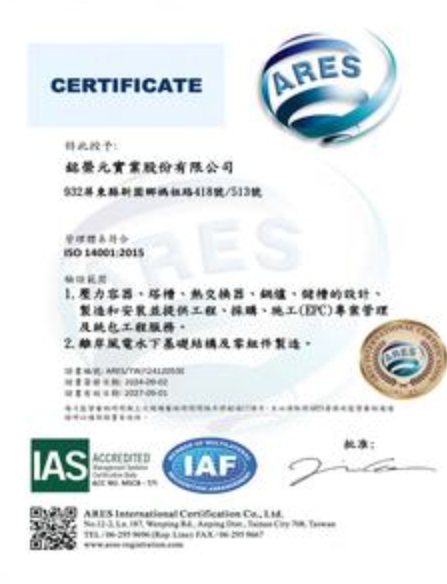

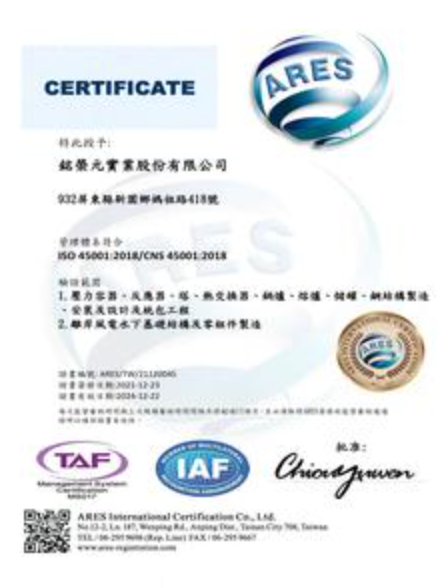

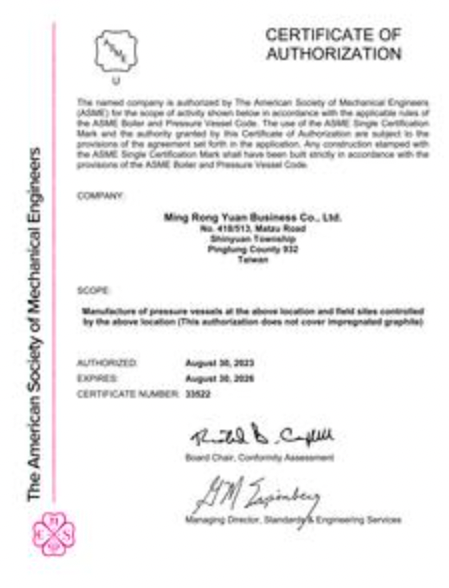

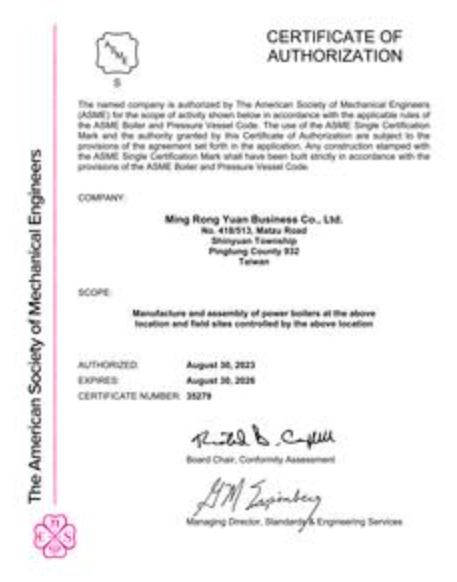

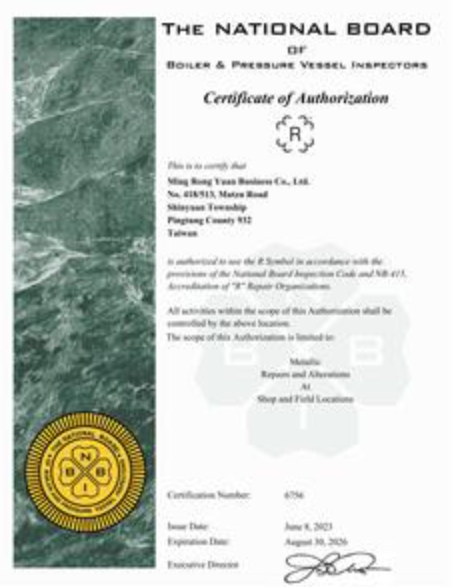

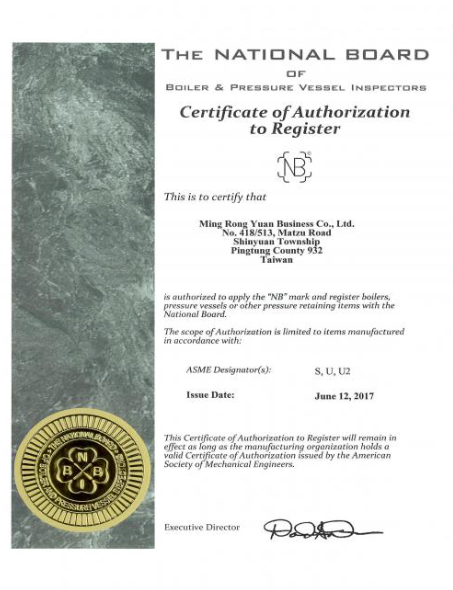

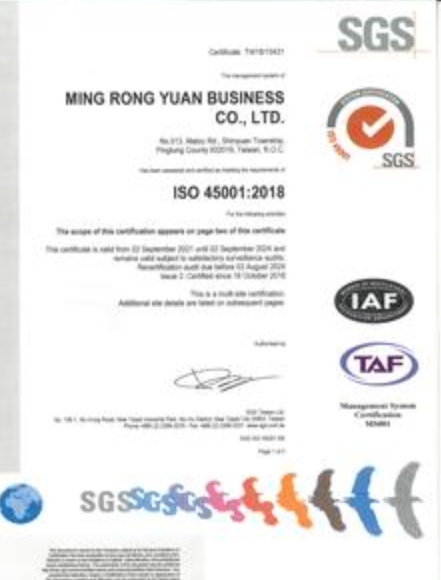

MRY is certified with ASME U, U2, S, R stamps ; PED and AD2000; ISO 3834-2 and EN 1090 ; ISO 9001 & ISO 45001 & 14001.

Modular Project

Since 2012, projects have included the design and manufacturing of a brine cooling unit, the SM3 ethylene adsorption bed module in 2016, the DHT modular engineering project in 2018, and in 2024, the Renewable Hydrotreator and Pre-treatment Unit projects.

Engineering

The main design departments include process design, piping design, equipment design, civil and structural design, instrumentation, and electrical design.

Our scope of services covers feasibility studies, project management, engineering design, equipment procurement, construction, commissioning, and EPC turnkey projects.